Disruptive Technologies in the Manufacturing Industry

With manufacturers trying to keep pace with consumer demand for high-quality products, companies must adopt data-driven technologies. This includes leveraging artificial intelligence (AI), augmented and virtual reality (AR and VR), 3D printing, and industrial internet of things (IIoT).

The areas of progress in conjunction with foundations of these technologies will improve production process through tracking and automation, while focusing on increasing throughput as well as output. Keep in mind, their use only scales when a strong technology foundation is laid — otherwise, new technology investments will be limited to specific initiatives.

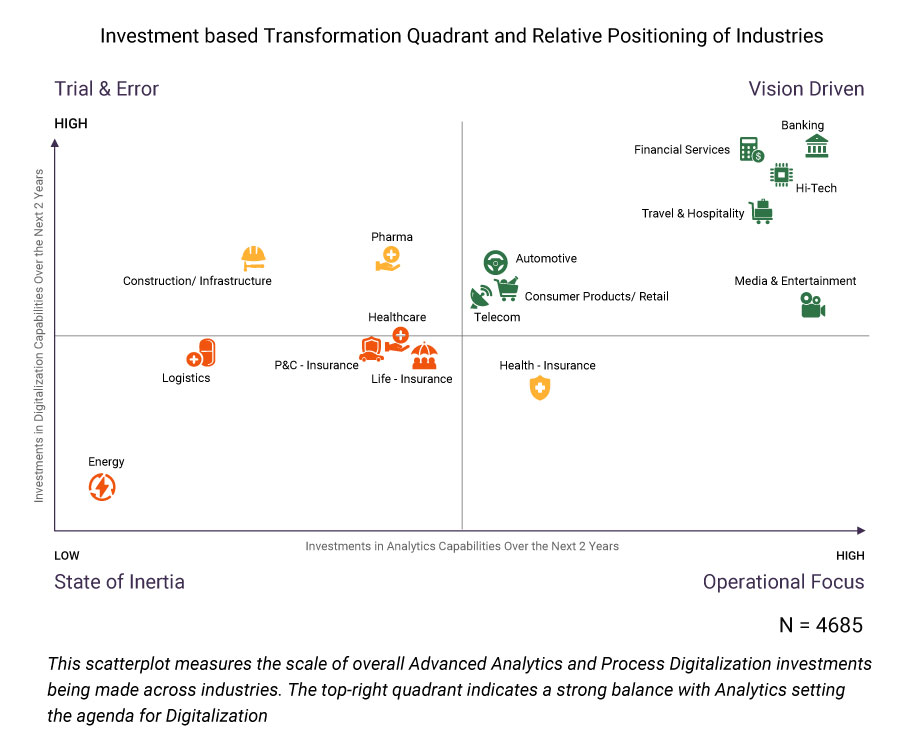

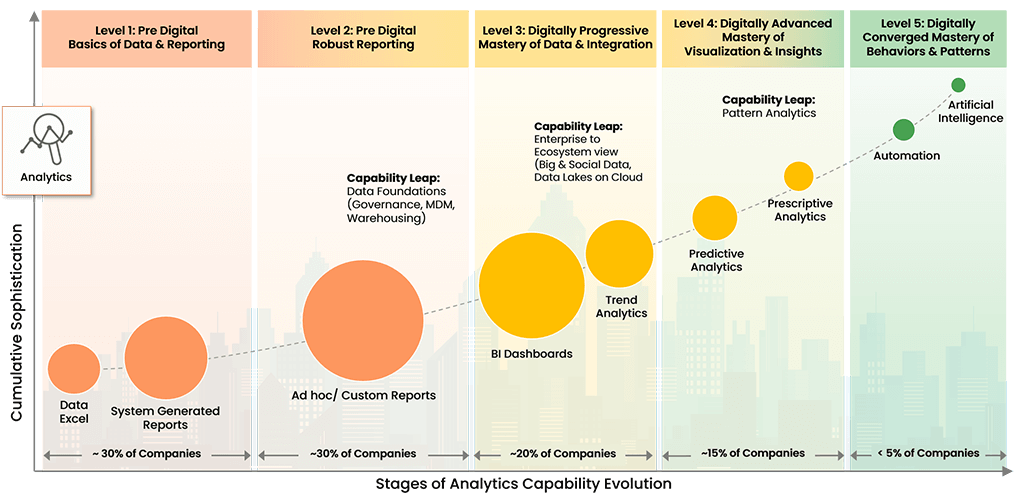

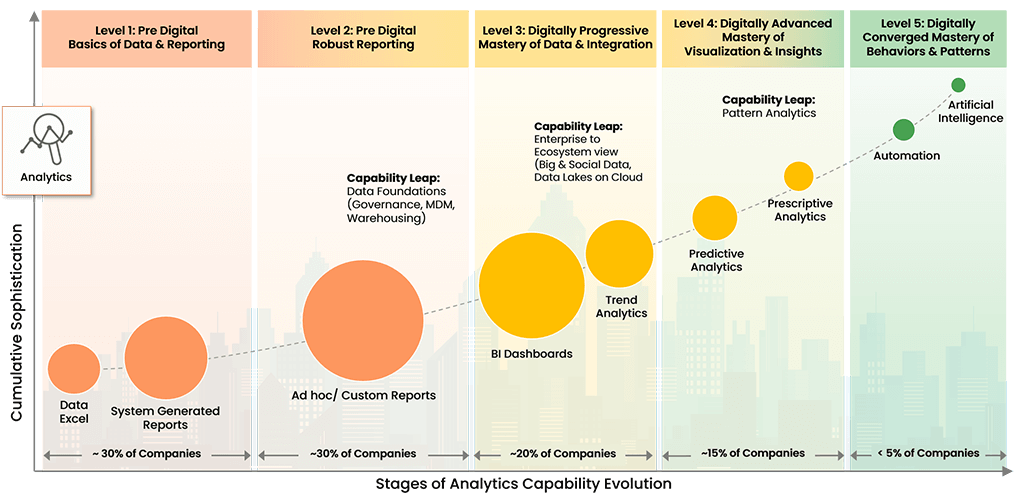

Only 7% of Companies Are Delivering on Their Transformational Initiatives

Our research has shown that 30% of companies will fail to survive this decade due to an inability to evolve digitally. To address this negative trend, we have developed the Digital Enterprise Evolution Model™ (DEEM).

Digital Enterprise Evolution Model™

Copyright © 2022 Trianz

DEEM allows our clients to recognize digital evolution patterns, implement benchmarking and prioritization strategies, and initiate application management protocols to satisfy stakeholder and market requirements.

Lack of Investment in IIoT in the Manufacturing Industry

Industrial internet of things (IIOT) is still not a priority for the manufacturing industry. Only 8% of the organizations in the manufacturing industry do not consider cloud for IIoT applications as a priority, and only 19% of the organizations are in the business case/justification stage.

With a stronger demand for customization, increasing customer expectations, and the growing complexity of the international supply chain — manufacturers need to take a serious look at IIoT to find more innovative ways to remain competitive.

IIoT can help manufacturers to maximize their business value through cost reduction, shorter time-to-market, production uptime, improved safety, and enhanced customization of manufacturing operations. By leveraging IIoT data, manufacturers can improve demand forecasting, gain a better understanding of the supply chain processes, and enhance the overall customer experience.

Human Capital Management (HCM) Among Manufacturing Companies

Manufacturing leaders plan significant future investments in advanced analytics for procurement service management and human capital. While most digital transformations across these two groups are reactions to competitive or customer-driven actions, predictive analytics will determine how, when, and to what extent to transform in the future.

By adopting cloud-based human capital management platforms to deliver analytics, manufacturers will not only be able to improve the employee experience but also leverage operational metrics to help stakeholders better understand employee contributions.

This will help manufacturers realize the urgency of upskilling and addressing the skill gap of their workforce. Additionally, leaders will recognize the requirement to transform employee learning functions and build new capabilities to attract, onboard, and retain employees.

Experience the Trianz Difference

Trianz enables digital transformations through effective strategies and excellence in execution. Collaborating with business and technology leaders, we help formulate and execute operational strategies to achieve intended business outcomes by bringing the best of consulting, technology experiences and execution models.

Powered by knowledge, research, and perspectives, we enable clients to transform their business ecosystems and achieve superior performance by leveraging infrastructure, cloud, analytics, digital and security paradigms. Reach out to get in touch or learn more.